Permanent Pavement Markings

Permanent Pavement Markings

We have the equipment and experience to install all types of permanent pavement markings both non durable and durable.

TRAFFIC PAINT

The most widely used pavement marking material

The lowest initial cost marking material and can be used on all pavement surfaces as both a temporary or permanent marking. In addition it can be used as a long line or a special marking. Traffic paint is considered a non durable marking needing annual restriping.

Waterborne Paint

As its name implies waterborne paint is water based. It is easy to clean up and is environmentally friendly, containing no Volatile Organic Compounds (VOC’s). It can be applied over any existing material and on any pavement surface. It is a non durable marking that must be applied when temperatures are at least 50 degrees. Its application season is May 1 – October 15.

Regular Dry Paint

Applied in the same fashion as waterborne paint and is used when temperatures are below 50 degrees, and between October 15 and May 1. Regular dry is solvent based contains VOCs and is therefore not as environmental friendly as waterborne paint.

High Build Waterborne

More durable version of traditional water based paint. It is applied thicker and lasts up to two years.

Thermoplastics

Thermoplastics can be formulated as a non-durable longline material that can be used on any pavement surface or as a durable long-line or special marking material on new asphalt. The granular or pelletized material becomes a liquid when melted down to 400+ degrees. Once applied it hardens as it cools.

Available in different Variations

40 Mil Sprayable Thermoplastic

Non-durable formulation that dries in less than one minute thus eliminating the use of cones to protect it while it dries. It can be used as a temporary or permanent marking on any pavement surface and requires a very short (one follow vehicle) convoy. It is applied at ambient temperatures above 50 degrees between April 15 and November 15.

90 Mil Extrude Thermoplastic

Highly durable formulation which lasts 3-5 years as a long line or special marking on new asphalt. It is applied at ambient temperatures above 50 degrees between May 1 and October 15.

Plural

Component

Materials

Plural

Component

Materials

Applied using specialized equipment that mixes two separate compounds to produce a durable marking with superior color retention and reflectivity.

Applied at ambient temperatures down to 40 degrees between April 15 and November 15. Depending on the optics used, Plural components can reach reflectivity levels that can exceed 1000 millicandelas (mcd) (standard paint is approximately 250 mcd). Careful surface preparation is required to ensure maximum bonding to the road surface.

Modified Urethane is another plural component material used in Michigan. As with polyurea, it is a durable marking. While its durability and color retention may be slightly less than polyurea it is a superior material compared to non durables and will last 3-5 years.

PREFORMED MARKINGS

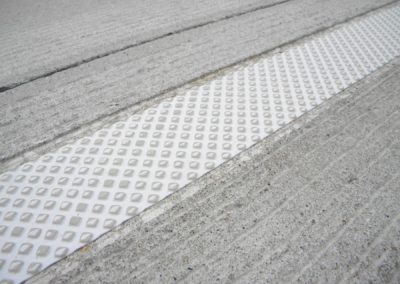

Permanent Pavement Marking Tape (Cold Plastic)

Permanent pavement marking tape is manufactured in different colors and widths and is available in rolls for longitudinal or transverse markings or as pre-cut symbols or legends. Permanent tape is available in different grades with the highest grade providing reflectivity levels exceeding 1000 millicandelas and is wet reflective.

Preformed Thermoplastic (Hot Tape)

This material shares the characteristics of both thermoplastic and preformed tape. It is a thermoplastic that is supplied in strips of different colors and widths or in preformed symbols and letters. The material is applied to the pavement and then fused to the surface by the use of propane torches. It is the most expensive durable material and is slow to apply but can be manufactured in various colors and shapes to produce very specialized markings

Recessed

Pavement

Markings

Recessing is a process where a groove is cut into the pavement surface that is slightly wider the marking being applied and slightly deeper than the thickness of the marking placed within it. The groove, cut by specialized equipment using diamond saw blades, protects the marking from damage caused by snow plows and maximizes the service life and reflectivity of the durable markings. Both longitudinal and special markings can be recessed.